Protect your instruments

Medical instruments are a big investment: make sure you’re protecting yours. Can you extend the life of your medical instruments? Learn more about how to protect your instruments, while ensuring that they’re safe and compliant to use.

Choosing the tools of your trade can be complex. According to the World Health Organisation there are an estimated two million different kinds of medical devices on the world market today, categorised into more than 7,000 generic device groups.

While the type of instrument may be dictated by your specific field of medicine, often your purchase choice will come down to your personal feelings, reputation of the manufacturer and cost of the tool under consideration. One thing is certain, your choice of instrument will impact the outcome of the treatment, surgery, or consultation. Making sure you pick the right tool for the right job is crucial.

Once you’ve made that investment, how do you ensure that your instruments are kept in the best condition possible, and can you extend their life with careful management? While gradual damage is often inevitable, it is possible to maintain the integrity of the instrument thorough careful handling and treatment.

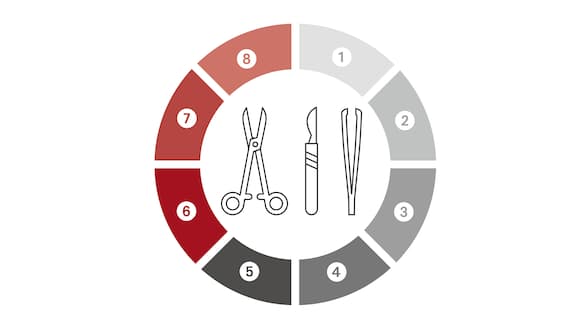

The instrument reprocessing procedure

Understanding the reprocessing procedure, as detailed here, will help you to ensure that instruments are well taken care of and fit for use.

1. Use:

During medical treatment, instruments and medical devices will become contaminated with organic soil, rinsing solutions and micro-orgamisms.

2. Pre-cleaning, disassembly, disposal:

During transportation contaminants are likely to adhere to the instrument. Leaving instruments for a long time without cleaning can cause discolouration, makes cleaning more difficult and increases the risk of corrosion.

3. Cleaning and disinfection:

Thorough and effective cleaning and disinfection is crucial to prevent the possibility of disease spreading from patient to patient or patient to employee. Practitioners need to ensure that their reprocessing processes adhere to government and industry standards and legislation, including European guidelines as MDR, EN 17664 and EN 15883. Examine the relevant steps of the process (amount of detergent, water quality, A0 value, etc.) as one incorrect element can cause material changes and incorrect cleaning. There are lots of solutions available for infection control – from washer disinfectors that offer great and standardised cleaning and disinfection performance, convenience, and process security, through to water treatment and process chemicals that deliver high throughput and gentle treatment of instruments.

4. Monitoring, care and functional test:

Review your instruments after cleaning and disinfecting. This visual test ensures that you pick up any wear or tear damage.

5. Packaging and labelling:

Use packaging to prevent medical devices from being recontaminated after sterislisation. Consider using a sterile barrier system – to ensure the sterility of the device – and protective packaging to keep the sterilised barrier system protected during transport or storage. It’s important that the type of packaging used lets the steam reach the devices, and allows them to adequately dry.

6. Sterilisation:

Ensure your instruments and devices are sterilised to a high standard. Consider a class B steriliser that conforms to the latest industry guidelines. Sterilisation will ensure that any instruments are free of micro-organisms, including bacterial spores, and will help support the continued lifespan of the instrument. Since the steam rapidly heats and penetrates materials quicker and harder than dry heat, the process is rapidly microbiocidal and sporicidal and it’s non toxic so gentle on the devices.

7. and 8. Storage and provisioning:

Once your instruments are clean, disinfected and sterilised, make sure that they’re stored and registered carefully to prevent cross-contamination.

It's important to think about investing in reprocessing equipment that combines careful processing with material compatability that will protect your instruments and your investment. Once you’ve invested in the tools of your trade, you need to make sure that you protect them. Taking time to consider their usage and their care is as important as the time you spent deciding which ones to buy. Once you have that process in place, your instruments will provide you with the support you need to deliver the best care you can.

How the Cube and Cube X can help to protect your investment:

- Shorter steam sterilising cycle times reduces exposure of the instruments

- EcoDry technology adjusts drying times to load sizes

- Instrument reprocessing is managed safely with three standard B-class cycles, one S-class cycle (Cube X only) and test programmes

Click here to learn more about the Cube and Cube X, or for more information, get in touch.