Compare

PDR 522 ROP [G]

Professional vented dryer, gas heating with M Select ROP residual moisture control for perfect drying results.

- Drum volume 14.13 (400) ft³ (l), load size 36 (16) lb (kg) – 50 (22.5) lb (kg)Note

Based on a load ratio of 1:25–1:18 - Unique, gentle fabric care – patented honeycomb drumHoneycomb drum

Less folding, easy finishing: Laundry is dried very gently and evenly in the honeycomb drum. - Greatest energy efficiency thanks to Air RecyclingAir recycling

Low energy consumption due to recycling of pre-heated process air. - Precision drying of all fabrics – PerfectDryPerfectDry system

On the basis of a constant residual moisture measurement, the PerfectDry system perfectly dries garments. - Connected for the future using LAN and WiFiAll the information you need

Prepared for connection to high-performance software solutions via WiFi. The LAN is connected via a separately available Miele Communication Module.*Note: the availability of the software solution is country-specific

Product benefits

Easy to understand symbols

Language-neutral operation

The control panel is characterized by logically arranged and easy to understand symbols.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

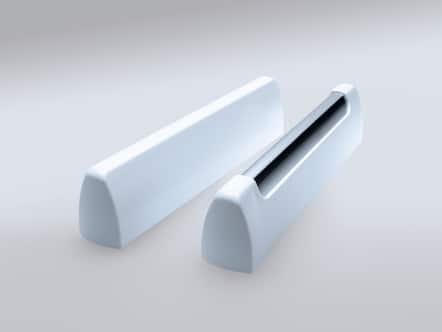

SoftLift drum ribs ensure gentle fabric care

Take it with you

The SoftLift drum ribs allow laundry to be dried gently and evenly.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Excellent durability

Ultimate quality

The professional technology ensures excellent reliability and durability for daily work routine,

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Easy to understand symbols

Language-neutral operation

The control panel is characterized by logically arranged and easy to understand symbols.

Large fluff filter

Simple to clean

The very large filter surface is particularly easy to clean.

Countdown indicator

An eye on the time

After the program has started, the display shows the cycle time remaining.

Subject to technical changes; no liability accepted for the accuracy of the information given! Figures as examples for showing the product benefit.

Product details

PDR 522 ROP [G]

EAN 4002516546467 / Article number 52522015NAM / Material number 12012250

EAN 4002516546467 / Article number 52522015NAM / Material number 12012250

| Design | Front loader |

|---|---|

| Linie | Performance |

| Front | Stainless Steel |

| Load size with a load ratio of 1:25 | 36 (16) |

| Load size with a load ratio of 1:18 | 50 (22.5) |

| Drum volume in ft³ (l) | 14.13 (400) |

| Drying system | Exhaust air |

| Door opening [Ø] in in.(mm) Large drum opening Large drum opening for fast, ergonomic loading and unloading ensures smooth operation. | 20 1/2 (520) |

| Door opening angle in degrees | 180 |

| Door hinging | left |

| Convertible hinging | |

| Stainless steel honeycomb drum |

| Maximum evaporation capacity in l/hour and gal. qts./hour Note In the Cottons/Normal drying program or with residual moisture reduced from 50% or 48% (depending on model) to 0% (with the lowest recommended load ratio). | 21 (21) gal (US)/min (l) |

|---|---|

| Specific energy consumption in kWh/kg an d kWh/p Note In the Cottons/Normal drying program or with residual moisture reduced from 50% or 48% (depending on model) to 0% (with the lowest recommended load ratio). | 0.55 |

| Program cycle in min. Note In the Cottons/Normal drying program or with residual moisture reduced from 50% or 48% (depending on model) to 0% (with the lowest recommended load ratio). | 25 |

| Tested operating hours Note Our machines undergo intensive testing under laboratory conditions. The actual operating hours may vary depending on actual usage behavior, maintenance, and care of the machine. | 20000 |

| Control system | M Select Benchmark |

|---|---|

| Programmability | Setting of defined parameters |

| Program controls | Residual moisture controlled |

| Max. delay start in h | 24 Delay start up to 24 hours The program start time can be pre-set up to 24 hours in advance for efficient planning. |

| Countdown indicator | |

| Fascia panel with easy-to-understand sym bols |

| Type of heating | Gas Gas heating Heating with gas has many benefits from an economic as well an environmental perspective. |

|---|---|

| Electrical connection | 208/240 V 60 HZ 2 PH |

| Gas heater rating in kW | 21.5 |

| Total connected load in kW | 1 |

| Fuse rating in A | 15 |

| External dimensions, net height in inches | 55 1/8 (1400) |

|---|---|

| External dimensions, net width in inches | 35 11/16 (906) |

| External dimensions, net depth in inches | 45 7/8 (1164) |

| External dimensions, gross height in inches Note Including packaging | 60 1/8 (1526) |

| External dimensions, gross width in inches Note Including packaging | 42 15/16 (1090) |

| External dimensions, gross depth in inches Note Including packaging | 49 3/8 (1254) |

| Net weight in lbs. (kg) | 450 (203.9) |

| Gross weight in lbs. (kg) Note Including packaging | 481 (218) |

| Maximum floor load in N Maximum floor bearing capacity Maximum floor bearing capacity states the maximum weight (N) that can be placed on the supporting surface on which the appliance is installed. This maximum load bearing capacity is the result of adding up the weight of the machine, the load and the water in it, as well as the dynamic forces that occur during operation. | 2570 |

| Emissions - sound pressure at workplace Emission sound pressure level in the workplace The emission sound pressure level is a value given to the noise created by the machine. Miele Professional commercial laundry appliances have very low noise levels. | 61 dB(A) re 20 µPa |

|---|---|

| Heat dissipation into the room in MJ/h Heat output into the room During operation, laundry machines release heat into the surrounding area. The released amount of heat/time depends on the set temperatures and the intensity of use. The stated maximum value can be used to control the temperature of the area or to calculate an increase in room temperature. | 2.6 |

| Intelligent drum reversal | |

|---|---|

| Axial airflow | |

| Large-surface fluff filter | |

| PerfectDry | |

| SoftLift drum ribs | |

| AirRecycling | |

| Communication slot | |

| Emergency shut off | |

| Machine-independent accessories | A wide range of accessories* Consistently perfect work processes and efficiency - with a large selection of practical accessories.All accessories can be purchased as an option. |

| Recycling rate in % | 91 |

|---|

| Payment system (optional) | |

|---|---|

| Optical interface for service access | |

| Peak-load negotiation / energy management (optional) | |

| Wi-Fi | |

| Connector Box | |

| LAN module (optional) |

| Cloths, 22 g/0.8 oz [number] | 364 |

|---|---|

| Summer horse blankets [number] | 3 |

| Splash-proof safety rating IPX4 | |

|---|---|

| c ETL US | |

| Complies with Machinery Directive 2006/42/EC |

Additional accessories and consumables

Find additional accessories and consumables to go with this product

Additional accessories for laundry technology

Find here the accessories that can be bought additionally for this product.

Downloads

You can download these CAD data for free. You will receive a download link via e-mail.

2D data DWG

3D data DWG

3D data FBX

3D data IFC

3D data RFA

3D data RVT